Soldering is an essential step in manufacturing copper pipes. It involves heating the metal and pressing it to create a durable bond that will prevent bending or cracking. With proper selection, your pipe can be produced quickly and efficiently.

(What Type Solder For Copper Pipe)

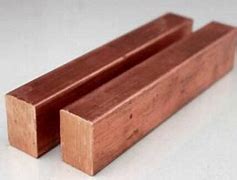

There are several types of metals that can be used for copper pipes. Here are some of the most common metals:

1. Gold: This metal has a beautiful color and shines when lit under the right conditions. It is commonly used in high-quality cures for copper pipes. However, gold may not be suitable for all applications, such as intricate designs or religious symbols.

2. Silver: Silver is a colorless metal that has a slightly malleable texture. It is often used in precision crafted parts, such as bends and turns. Silver is also a good choice for religious symbols or intricate designs.

3. Chrome: Chrome is a white metal that has a tough, shiny surface. It is often used in electrical components and hardware. Chrome is not suitable for all applications, such as use in heavy-duty machinery.

4. Iron: Iron is a heavy metal that has a reddish-brown hue. It is commonly used in food and beverage processing. Iron is also a good choice for plumbing fixtures, but it may not be suitable for general-purpose applications.

5. Aluminum: has a sleek, lightweight appearance and excellent conductivity. It is commonly used in structural components, such as taps and. Al rounded edges can make them more stable than standard metal ones.

When selecting a type of soldering wire for your copper pipe, there are several factors to consider. First, the wire’s type and diameter will affect its ability to grip the metal being cooked. Second, the wire’s resistance to corrosion will depend on how much you want to minimize your final product’s lifespan. Finally, the wire’s price will vary depending on the quality and durability it is made from.

(What Type Solder For Copper Pipe)

In conclusion, choosing the right type of soldering wire is crucial to producing high-quality copper pipes. By considering the material and diameter of the wire, as well as the resistance to corrosion and the quality of the iron and aluminum used in your piece of equipment, you can ensure that your copper pipe is both functional and long-lasting.