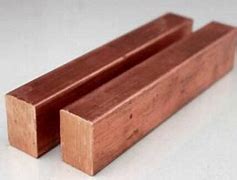

Title: What to Use in Lieu of Solder Paste for Coppers

(What To Use In Lieu Of Solder Paste For Copper Pipes)

When it comes to pipes, choosing the right tool can make all the difference. Whether you’re building a new pipe or updating an old one, there’s no substitute for the right tool. One such tool is paste, which is used to connect copper pipes to their ends.

There are several types of paste available on the market, each with its own strengths and weaknesses. However, one type of paste that’s widely used is the jolly mix of hot air and water. This mixture helps to create a chemical reaction between the two materials, forming a solid bond that can be adhered to the surface of the pipe.

When using paste, it’s important to choose the right type of paste based on your needs. Some people prefer higher paste, while others prefer lower paste. It’s also important to consider the type of equipment you’ll be working with, as high paste may cause more damage to the pipe than low paste.

One benefit of using a high paste is that it can help to reduce the risk of smudging and scaling. This is because the high concentration of the gas creates a defined bond between the two materials, which helps to prevent them from smudging together or scaling over time.

Another benefit of using a high paste is that it can help to protect against corrosion. Corrosion is a common issue for pipes, but using a high paste can help to prevent it. The high concentration of the gas creates a surface that’s less likely to be damaged by moisture or other substances.

It’s also worth noting that paste doesn’t cure rust immediately. Instead, it takes time for the rust to wear off and fully settle. Therefore, if you need to repair or replace a copper pipe after it has been exposed to a heavy dust storm, it’s important to use a higher paste to speed up the process.

(What To Use In Lieu Of Solder Paste For Copper Pipes)

In conclusion, paste is a valuable tool when it comes to connecting copper pipes to their ends. With the right type of paste, you can help to ensure that your pipe is safe and reliable for years to come. But just remember to choose the right type of paste based on your specific needs and work with high-quality equipment.