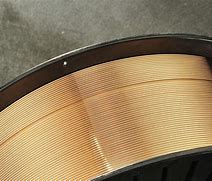

Soldering is an important skill in many different areas, including electrical engineering and metalworking. One type of solder that is commonly used for copper pipes is tin-solder.

(What Kind Of Solder For Copper Pipe)

Tin-solder is a clear, pure metal that is melted at high temperatures and then poured into a joint to bond two pieces together. It has several advantages over other types of solder, including its excellent adhesion to copper, which makes it easy to remove when the joint needs to be repaired or replaced.

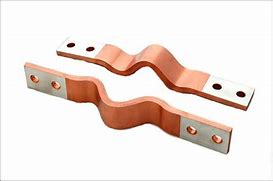

One advantage of using tin-solder for is that it can bond evenly and securely, without leaving small gaps or weaknesses that could cause the pipe to fail under pressure or stress. This makes it particularly useful for long-term applications, such as plumbing systems or electrical components.

Another benefit of tin-solder is that it is relatively inexpensive compared to other types of solder. While it can be more expensive than other types of solder in certain situations, such as when working with very small joints or when precision is required, tin-solder is generally a more affordable option overall.

There are also some potential disadvantages to using tin-solder for. One potential issue is that it can be difficult to remove from a joint if it gets too hot, as this can cause it to melt and become damaged. Additionally, tin-solder can have a slightly different melting point than other types of solder, which may affect the performance of the joint.

(What Kind Of Solder For Copper Pipe)

Despite these potential drawbacks, tin-solder remains a popular choice for due to its strong bonds, ease of use, and affordability. Many different types of solder are available on the market, each with its own unique properties and advantages. As a result, it’s important to choose the right type of solder for the job at hand, taking into account factors such as the type of being used, the desired strength and durability of the joint, and the expected temperature and environment in which the joint will operate.