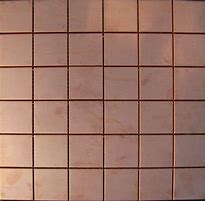

Title: What Happens When Over Heat Copper Pipe When Soldering

(What Happens When Over Heat Copper Pipe When Soldering)

Introduction

Overheating copper pipes when subjected to high temperatures during soldering can result in various negative consequences, including corrosion, damage to the final product, increased labor costs, and potential hazards for the.

What Happens when Overheat Copper Pipe When Soldering

When copper pipes are subjected to high temperatures during soldering, they undergo a process called thermal expansion. This occurs due to the increase in the internal temperature of the pipe, which is greater than the ambient temperature. As the heat rises within the pipe, it causes changes in its chemical composition and material properties. The materials such as metal, plastic, and rubber can start to dissolve and form water. This process can lead to the breakdown of the pipe, making it more prone to rusting and other problems.

In addition to this, overheating can also cause damage to the pipe. The rapid expansion of the water will tend to expand the metal layer that forms at the top of the pipe, leading toaging, cracking, or tearing. This phenomenon can be especially dangerous if the material being sanded is not properly designed or if the field conditions are unsuitable.

Potential Hazards

Furthermore, overheating can have significant impacts on the’s health. It increases the risk of accidents, such as fire, electrical injuries, and respiratory problems. In addition, the stress and strain that comes with working under conditions can lead to physical disabilities, particularly those who are unable to maintain proper posture or work for extended periods.

Conclusion

(What Happens When Over Heat Copper Pipe When Soldering)

In conclusion, overheating copper pipes during soldering poses several risks, including the failure of the final product, increased labor costs, and potential hazards for the. It is crucial to take steps to prevent and mitigate these issues before the heat takes hold and damage occurs. Therefore, proper design, appropriate materials selection, and careful handling by workers are essential components of ensuring the safe and effective operation of copper pipes during soldering.