A copper Wire Drawing Machine is a mechanical equipment used to process coarse copper wire into fine copper wire. Through the gradual stretching of multi-stage molds, the copper wire drawing machine can reduce the diameter of copper wire from a few millimeters to tens of micrometers while maintaining the mechanical and electrical properties of the copper wire.

Copper Wire Drawing Machine

Copper wire drawing machine is widely used in the fields of wire and cable manufacturing, electronic component production, power transmission, etc. It is an indispensable and important equipment in modern industrial production. The copper wire drawing machine adopts advanced CNC technology and precision molds, which can achieve high-precision copper wire stretching and ensure the consistency of copper wire size and shape. This not only improves production efficiency but also ensures product quality.Modern copper wire drawing machines are usually equipped with multiple functions, such as automatic mold changing, automatic lubrication, tension control, etc., which can adapt to the processing needs of copper wires of different diameters and materials. These features not only enhance the flexibility of the device but also reduce operational difficulty and maintenance costs. The copper wire drawing machine adopts an efficient transmission system and energy-saving design, which can reduce energy consumption while ensuring production efficiency. This is of great significance for reducing production costs and improving the competitiveness of enterprises.The copper wire drawing machine is equipped with various safety protection devices, such as emergency stop buttons, overload protection, etc., to ensure the safety and reliability of the equipment during operation. This not only protects the safety of operators but also reduces equipment failures and maintenance time.

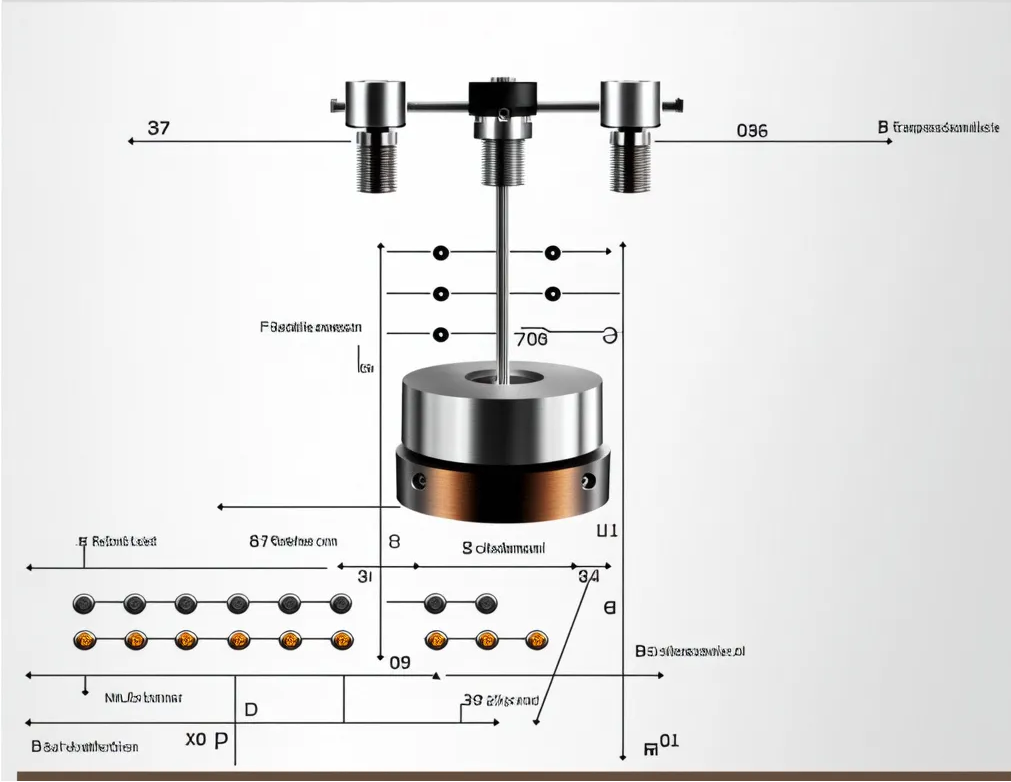

The main components of Copper Wire Drawing Machine

With the recovery of the global economy and the increase in infrastructure construction, the demand for wires and cables continues to grow. Especially in emerging market countries, there is a huge demand for the construction of power transmission and distribution systems, and the demand for high-quality copper wire drawing machines has also increased. The wire and cable manufacturing industry is one of the largest application areas for copper wire drawing machines. The demand for copper wire in the electronic component manufacturing industry is also constantly increasing.With the miniaturization and high performance of electronic products, the demand for thin copper wires is increasing. The copper wire drawing machine can produce fine copper wires with a diameter of only a few tens of microns, meeting the special needs of electronic component manufacturing. The demand for copper wire in power transmission and distribution systems is steadily increasing. With the development of new energy and smart grids, the demand for high-performance and high-reliability copper wires is constantly increasing.

The application of copper wire drawing machines in this field is becoming increasingly widespread. Many countries and regions have introduced relevant policies to encourage the use of efficient and environmentally friendly production equipment. For example, China’s “Made in China 2025” plan clearly proposes to develop the high-end equipment manufacturing industry and improve the automation and intelligence level of equipment. These policies not only promoted the market popularization of copper wire drawing machines but also improved the technical level of the entire industry.With the advancement of technology, the technology of copper wire drawing machines is also constantly upgrading. The future copper wire drawing machine will be more efficient and intelligent and have better stability and reliability. For example, by adopting advanced numerical control technology and artificial intelligence, more precise copper wire stretching and automated production processes can be achieved, improving production efficiency and product quality. Environmental protection has become a global consensus, and more and more companies are using recyclable or low-energy materials to manufacture copper wire drawing machines. This not only conforms to the concept of sustainable development but also reduces production costs and enhances the market competitiveness of enterprises.

For example, some companies are developing copper wire drawing machines based on new materials, which are not only environmentally friendly but also have good performance. The introduction of intelligence and IoT technology will make the application of copper wire drawing machines more intelligent. By integrating sensors and wireless communication modules, the operating status of equipment can be monitored in real-time, production parameters can be automatically adjusted, and the best production results can be ensured. This intelligent solution will greatly improve production efficiency and reduce maintenance costs.With the recovery of the global economy, the manufacturing industry of wires, cables, and electronic components will continue to maintain a growth trend. Especially in emerging markets such as Asia and Africa, the demand for infrastructure construction will continue to increase, which will bring broad market space for copper wire drawing machines. It is expected that the market growth rate in these regions will be higher than the global average in the coming years. In order to meet the needs of different customers, enterprises will continuously launch new product lines.

For example, developing copper wire drawing machines with different diameters, materials, and functional characteristics for different application scenarios to meet the diverse needs of the market. In addition, the company will strengthen product research and development and launch more high-performance and environmentally friendly products to meet the demands of the high-end market. In addition to the product itself, enterprises will also pay more attention to after-sales service and customer experience. Provide professional technical consultation, on-site guidance, and training services to help customers better use copper wire drawing machines and solve problems encountered in production. By establishing a comprehensive after-sales service system, we can improve customer satisfaction and loyalty and enhance the market competitiveness of the enterprise.Copper wire drawing machines, as high-performance production equipment, have become indispensable and important equipment in the manufacturing industry of wires, cables, and electronic components due to their high precision, multifunctionality, high efficiency, energy saving, and safety and reliability. With the continuous advancement of technology and the continuous expansion of the market, copper wire drawing machines will be applied in a wider range of fields in the future, providing strong guarantees for the high-quality development of related industries. Enterprises should seize this opportunity, continuously innovate, and improve product quality and service levels to meet the diverse needs of the market.

In the future, copper wire drawing machines will develop towards higher efficiency, intelligence, and environmental friendliness, promoting technological progress and sustainable development of the entire industry. With the increasing global emphasis on environmental protection and sustainable development, the application prospects of copper wire drawing machines will be even broader. Through technological innovation and market expansion, enterprises can occupy a favorable position in this market full of opportunities and make greater contributions to the high-quality development of the wire and cable and electronic component manufacturing industry.With the acceleration of global urbanization and the continuous upgrading of industrial production, copper wire drawing machines will play an important role in more fields and become an important force in promoting economic development. Enterprises should seize this opportunity, continuously innovate, improve product quality and service levels to meet the diverse needs of the market and make greater contributions to the high-quality development of related industries.

Supplier

CopperGroup is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality copper and relative materials. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, Coppergroup dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for Copper Wire Drawing Machine, please send an email to: sales8@nanotrun.com