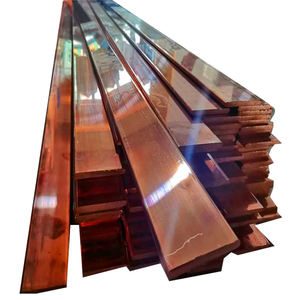

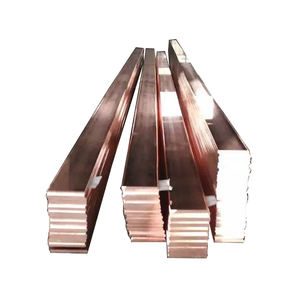

Irregular Copper Bar Overview

Irregular copper bars are special-shaped conductive materials made of copper. Its cross-sectional shape is not square or rectangular, with various shapes, including “L” – shaped, “T” – shaped, ladder-shaped, polygonal and polygonal shaped, etc., mostly depending on the specific product design requirements of the manufacturer.According to user needs, customize according to drawings and samples.

Irregular Copper Bar Feature

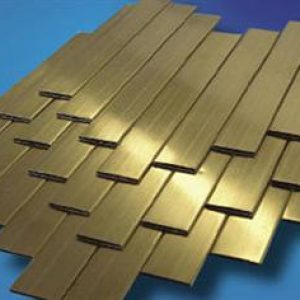

Irregular copper bars are electrical conductors with high conductivity, safety, and reliability. They are widely used in fields such as transformers, cables, switchgear, and bus ducts. Compared to other electrical conductors, special-shaped copper bars have excellent conductivity, thermal conductivity, and mechanical properties and can withstand higher current carrying capacity and larger transient currents.

In addition, irregular copper bars are widely used in fields such as electronics, communication, and industrial heat exchange. For example, they can be used in electronic components such as contact plates, relays, switches, etc. They can also be used as a material for wireless base station antennas, computer motherboard heat sinks, etc. Due to their strong corrosion resistance, special-shaped copper bars can also be used for building exterior walls, roof decoration, etc.

In the manufacturing process, continuous extrusion technology is mainly used for irregular copper bars. This method continuously extrudes copper bars of different specifications through molds to obtain the desired shape. This method simplifies the process flow, improves production efficiency, and results in high output, good surface quality, excellent electrical performance, and energy conservation and environmental protection of shaped copper bars.

Irregular Copper Bar Application

Electrician and electrical industry: Irregular copper bars are the main raw materials for manufacturing large motors, high- and low-voltage electrical switch contacts, and wires for power supply (distribution) installation. In electrical manufacturing, irregular copper bars are often used to construct electrical connections because they have excellent conductivity and mechanical strength.

Power transmission and transformation industry: In the power system, irregular copper bars are a key component in building infrastructure such as power grids and substations. They carry and transmit large currents, ensuring a stable supply of electrical energy.

The new energy vehicle and high-efficiency motor industry: With the rapid development of new energy vehicles, special-shaped copper bars play an important role in key components such as motors and batteries. Their excellent conductivity helps to improve the efficiency and performance of the motor.

In the fields of semiconductors, chips, and consumer electronics:high-precision copper straight tubes, high-precision copper alloy tubes, and other special-shaped copper bar products play a crucial role in the production and manufacturing process, ensuring the stable operation of these precision equipment.

Communication industry: The application of irregular copper bars in fields such as 5G communication and lasers is becoming increasingly widespread. They are used to build internal connections for communication devices, ensuring high-speed and stable transmission of information.

In architecture:special-shaped copper bars are mainly used for building decorations such as ceilings, roofs, walls, doors, and windows. They not only provide conductivity but also increase aesthetics and durability.

Company Profile

Copper Channel is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality Irregular copper bar, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of Irregular Copper Bar

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of Irregular Copper Bar

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

What problems may occur during the use of Irregular copper bar?

Answer: Common problems include poor contact, loose connections, breaks, oxidation corrosion, etc. These problems may be caused by improper installation, harsh use environment, poor material quality, etc.

How to solve the problem of poor copper bus contact?

Answer: The connection of the copper bars should be checked regularly to ensure good contact. For copper bars with poor contact, the dirt should be cleaned in time, the wiring position should be adjusted, and the wiring terminals should be tightened.

What are the precautions for the installation and maintenance of Irregular copper bar?

Answer: During installation, ensure that the copper bars are firmly connected and in good contact, and avoid excessive bending or stretching. During maintenance, the connection status should be checked regularly, and damaged copper bars should be replaced in time to maintain good conductive properties.

What factors affect the price of copper strips?

Answer: The price of copper busbars is affected by many factors such as copper price, production process, specifications and sizes, and market demand. Among them, fluctuations in copper prices have a greater impact on copper bar prices.

How to judge the quality of Irregular copper bar?

Answer: It can be evaluated from the aspects of appearance, conductive properties, mechanical properties, etc. A high-quality copper busbar should have a smooth appearance and no damage; its electrical conductivity should be stable and reliable; its mechanical properties should meet relevant standards. In addition, factors such as product certification and brand reputation can also be considered.

How to prevent oxidative corrosion of Irregular copper barduring use?

Answer: Measures such as coating an insulating layer, regularly cleaning surface dirt and oxides, and avoiding contact with corrosive substances can be taken to extend the service life of the copper busbar.