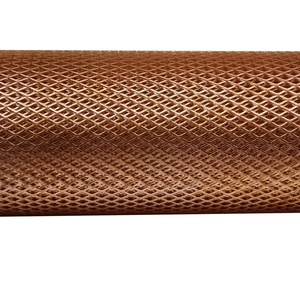

(Enameled copper wire)

Parameters of Enameled copper wire

The parameters for enameled copper wire typically refer to the physical properties of the wire, such as its resistance, capacitance, and inductance.

The resistance of enameled copper wire is typically measured in ohms (Ω). It is influenced by factors such as the diameter of the wire, the temperature at which it is used, and the material it is made from.

The capacitance of enameled copper wire is also important, as it depends on the length and cross-sectional area of the wire. It can be measured using a capacitance meter.

The inductance of enameled copper wire is often referred to as its magnetic field resistance, and it is also affected by factors such as the thickness of the wire and the surrounding magnetic environment.

Overall, the parameters for enameled copper wire are carefully controlled to ensure that they meet specific performance requirements, such as maximum current carrying capacity and electrical stability.

(Enameled copper wire)

Applications of Enameled copper wire

-

Electrical Wiring: Used extensively in building wiring for lighting, heating, and power distribution due to its high conductivity and safety.

-

Electronics: Found in PCBs, transformers, motors, and various electronic components where precise signal transmission is crucial.

-

Telecommunications: Copper wires, especially twisted pairs, are used in telephone lines and data transmission cables.

-

Power Transmission: Thicker copper wires are used in power grids for transmitting electricity over long distances.

-

Automotive Industry: Copper wiring is essential in vehicles for the electrical system, including ignition, lighting, and control systems.

Company Profile

Copper Channel is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality copper products and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Enameled copper wire

Q: Why is copper used more than other metals for wiring?

A: Copper’s high conductivity, combined with its relatively low cost compared to precious metals like gold or silver, makes it the preferred choice for electrical wiring applications.

Q: Is Enameled copper wire insulated?

A: No, not all copper wires are insulated. Bare copper wire is used in grounding applications and where direct contact with other conductive materials is intended.

Q: How do you determine the gauge of a Enameled copper wire?

A: The gauge of a Enameled copper wire refers to its diameter and is typically measured using the American Wire Gauge (AWG) system, where a lower number indicates a thicker wire.

Q: Can Enameled copper wire be recycled?

A: Yes, copper is highly recyclable. Old or scrap copper wire can be melted down and reused without losing its properties, making it an environmentally friendly material.

Q: What is the difference between stranded and solid copper wire?

A: Solid copper wire consists of a single, unbroken strand, whereas stranded copper wire is composed of multiple thinner wires twisted together, providing increased flexibility and durability, especially in applications where frequent movement or bending occurs.

(Enameled copper wire)