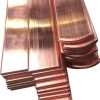

Overview of Customizable Pure 99.9% copper cathode flat round bus bar

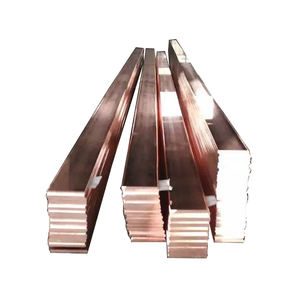

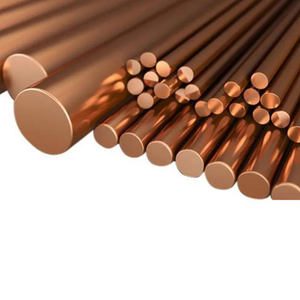

A copper bar, also known as copper billet or ingot, refers to a solid, rectangular or square-shaped piece of pure copper or copper alloy. These bars are characterized by their robustness, dimensional accuracy, and metallurgical consistency, making them ideal for applications requiring high mechanical strength and/or electrical conductivity. Copper bars are typically produced through casting, extrusion, or hot rolling processes, resulting in a range of sizes and shapes to accommodate diverse industrial needs. They can be supplied in standard lengths or custom-cut to specific dimensions based on the end-user’s requirements.

Copper Bar of Customizable Pure 99.9% copper cathode flat round bus bar

-

Strength and Durability: Copper bars exhibit good mechanical strength and toughness, enabling them to withstand high stress loads without fracturing.

-

High Conductivity: Like other copper forms, copper bars offer excellent electrical and thermal conductivity, which is essential in electrical and heat transfer applications.

-

Corrosion Resistance: Copper naturally corrodes at a slow rate and forms a protective patina, making it resistant to atmospheric corrosion and suitable for prolonged exposure to the elements.

-

Workability: Copper bars can be easily machined, drilled, turned, or otherwise fabricated into intricate shapes and components without compromising their integrity.

-

Versatility in Alloys: Copper can be alloyed with other metals to create bars with customized properties, such as increased hardness, wear-resistance, or specialized temperature and pressure tolerance.

Applications of Customizable Pure 99.9% copper cathode flat round bus bar

-

Machinery and Equipment: Copper bars are used in the production of heavy machinery components, gears, and bearings due to their strength and wear resistance.

-

Construction: For structural applications, electrical grounding systems, and architectural accents where both strength and aesthetics are desired.

-

Electrical Engineering: In the fabrication of busbars, switchgear components, and transformer parts where high electrical conductivity and durability are needed.

-

Transportation Industry: Copper bars are integral to the production of parts for automobiles, railways, and aerospace due to their combination of strength and conductivity.

-

Forging and Casting: Serves as raw material for further manufacturing processes like forging into intricate shapes or melting down for casting complex components.

(Customizable Pure 99.9% copper cathode flat round bus bar)

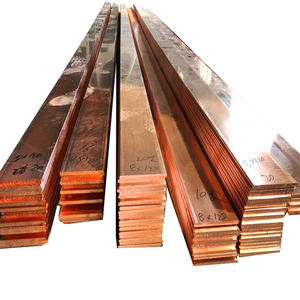

Parameters of Customizable Pure 99.9% copper cathode flat round bus bar

The Pure 99.9% copper cathode flat round bus bar parameters can vary depending on the specific application and requirements of your project. However, here are some general guidelines that you can use to determine the appropriate values for your needs:

1. Material: The type of copper cathode used will affect its performance in various applications. For example, lead-based cathodes may be preferred for high-speed transmission applications while cobalt-based cathodes may be more suitable for precision critical applications.

2. Temperature: The temperature range for the metal is an important factor to consider. Copper is a ductile metal at room temperatures, but it decreases with increasing temperature due to reduced hydrogen content. Therefore, a variety of temperatures should be considered, such as room, ambient, and industrial standards.

3. Sheath and Introducing: The surface finish of the bus bar should also be taken into account when determining the performance. High-speed transmission applications often require seamless surfaces, while precision critical applications may require tough and durable steel sheaths.

4. Conditions: The conditions of storage and transport can impact the performance of the bus bar. Moisture, air exposure, and humidity can affect the conductivity and resistance of the metal. Ensure proper handling and storage to minimize these effects.

5. Price: is another important consideration when choosing a custom-made bus bar. While some suppliers may charge higher prices due to quality control and specialized equipment, other manufacturers offer competitive prices based on their production capacity and competitiveness.

In summary, the precise selection of parameters for your custom-made Pure 99.9% copper cathode flat round bus bar will depend on factors such as material, temperature, substrate finish, high-speed transmission requirements, and storage and transport conditions. It’s recommended to consult with experts or conduct market research to determine the best options for your specific needs.

(Customizable Pure 99.9% copper cathode flat round bus bar)

Company Profile

Copper Channel is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality copper products and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Customizable Pure 99.9% copper cathode flat round bus bar

Q: What is the standard size for Customizable Pure 99.9% copper cathode flat round bus bar?

A: Copper bars are available in a variety of sizes, with common dimensions ranging from small squares or rectangles of a few millimeters in thickness to large sections several inches thick and wide. Exact sizes can be customized to order.

Q: Can Customizable Pure 99.9% copper cathode flat round bus bar be welded?

A: Yes, Customizable Pure 99.9% copper cathode flat round bus bar can be welded using various techniques, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW), although proper preparation and technique are necessary to avoid issues like porosity.

Q: Is Customizable Pure 99.9% copper cathode flat round bus barsuitable for marine environments?

A: Yes, copper’s inherent corrosion resistance makes it suitable for use in marine applications, although specific alloys may be preferred for added protection against saltwater corrosion.

Q: How does the cost of Customizable Pure 99.9% copper cathode flat round bus bar compare to other metals?

A: Copper tends to be more expensive than some common structural metals like steel due to its higher conductivity and relative scarcity, but its unique properties often justify the cost in specialized applications.

Q: Is Customizable Pure 99.9% copper cathode flat round bus bar recyclable?

A: Absolutely, copper is one of the most recycled metals globally. Copper bars can be melted down and reused repeatedly without losing their inherent properties, contributing to a circular economy and sustainable practices.

(Customizable Pure 99.9% copper cathode flat round bus bar)