Copper Foil Tape Overview

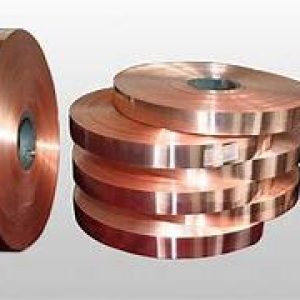

Copper foil is divided into two categories: rolled copper foil and electrolytic copper foil.

Electrolytic copper foil is an important material in the manufacturing of copper clad laminates (CCL) and printed circuit boards (PCB). In today’s rapid development of the electronic information industry, electrolytic copper foil is called the “neural network” for signal and power transmission and communication in electronic products.

Copper Foil Tape Features

Rolled copper foil is mainly used for electromagnetic shielding and antistatic. The conductive copper foil is placed on the substrate surface and combined with the metal substrate to have excellent conductivity and provide electromagnetic shielding effect.

- High persistence active substances

- 2.Excellent tensile strength

- High elongation

- Available micron thickness range

Copper Foil Tape Specification

Thickness: 0.1-0.01mm

Copper Foil Tape Application

Widely used in industrial calculators, communication equipment, QA equipment, lithium-ion batteries, consumer televisions, video recorders, CD players, copiers, telephones, heating and cooling air conditioners, automotive electronic components, game consoles, etc.

Company Profile

Copper Channel is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of Copper Foil Tape

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of Copper Foil Tape

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

What is the production process of copper strips?

Answer: The production process of copper strips includes multiple steps such as smelting, casting, hot rolling, cold rolling, annealing, and finishing. By controlling parameters such as temperature, pressure, and cooling rate, copper strips with required properties can be obtained.

How to judge the quality of copper strip?

Answer: The quality of copper strips can be judged by examining its appearance (such as surface finish, flatness), physical properties (such as conductivity, tensile strength), and chemical composition.

Why does the copper strip bend and deform during use?

Answer: The bending deformation of copper strips during use may be caused by improper annealing process, uneven stress distribution during cold working, excessive impurities inside the material, or external environmental influences (such as temperature changes).

What is the reason for oxidation or corrosion on the surface of copper strip?

Answer: Oxidation or corrosion on the surface of the copper strip may be caused by a humid storage environment, contact with corrosive substances, improper surface treatment, or poor corrosion resistance of the material itself.

How to choose the appropriate copper strip specifications?

Answer: Choosing appropriate copper strip specifications needs to be considered based on specific application scenarios, such as current capacity, mechanical strength, usage environment and other factors. Cost factors also need to be considered.

Why does the copper strip break during use?

Answer: The fracture of the copper strip during use may be caused by defects in the material itself (such as pores, cracks), stress concentration during processing, harsh use environment (such as high temperature, corrosion), etc.

How to store and maintain copper strips?

Answer: When storing and maintaining copper strips, ensure that the environment is dry and ventilated, and avoid contact with corrosive substances. For long-term storage of copper strips, regular inspection and maintenance should be carried out to ensure stable performance.

What factors affect the price of copper strips?

Answer: The price of copper strips is affected by many factors, including raw material prices, complexity of production processes, market demand and supply, fluctuations in international copper prices, etc. The prices of copper strips of different specifications and qualities will also vary.