Brass Bar Overview

Brass bar is a high-current conductive product that is widely used in high- and low-voltage electrical appliances, switch contacts, distribution equipment, bus ducts and other electrical engineering projects. It is also commonly used in metal smelting, electrochemical plating, chemical caustic soda and other ultra-high current electrolytic smelting projects. It is brightly colored and highly decorative, so it is also widely used in architectural decoration, furniture production and other fields.

It can be used to make various deep-drawn and bent stress-bearing parts, such as pins, rivets, washers, nuts, conduits, air pressure gauges, screens, radiator parts, etc.

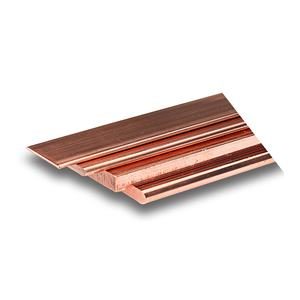

The brass row is mainly composed of copper (Cu) and zinc (Zn), and its chemical composition is rich and stable. Copper has excellent electrical and thermal conductivity, and the addition of zinc can enhance the strength and corrosion resistance of brass. Ordinary brass rows have good plasticity and forgeability, and can be processed into products of different shapes and sizes. Compared with other metals, brass has moderate hardness and is easy to machine and heat treat.

Brass Bar Feature

Brass row has high strength and good plasticity. It is suitable for cold and hot processing. It has good weldability and corrosion resistance. It is used for condensation and heat dissipation tubes, serpentine tubes, siphons, and cooling equipment parts. It has good mechanical properties and thermal properties. It has good plasticity, good machinability, weldability and corrosion resistance, and is suitable for various deep extension and bending stress-bearing parts, such as pins, nuts, barometer springs, heat dissipation, and ring parts.

Brass row material: H62, H62, H63, H65, H68, H70, H80, H85, H90, H96, T1, T2, C1100, C5111, C5101, C5191, C5210, TU1, TP1, TP2, TAg0.08, TAg0 .1. C1100, C1020, C1201, C1220, C1271, C2100, C2200, C2300, C2400, C2600, C2680, C2700, C2720, C2800, C2801, C3604w, etc.

Brass Bar Parameter

| 3series | 3*15 | 3*20 | 3*25 | |||||||

| 4series | 4*30 | 4*40 | ||||||||

| 5series | 5*40 | 5*50 | ||||||||

| 6series | 6*50 | 6*60 | 6*100 | |||||||

| 8series | 8*60 | 8*80 | 8*100 | 8*120 | ||||||

| 10series | 10*60 | 10*100 | 10*120 | |||||||

| Square Rod | 10*10 | 20*20 | 30*30 | 40*40 | 50*50 | 60*60 | 70*45 | 75*30 | 80*20 | 100*35 |

Brass Bar Application

In the electrical field, brass strips are widely used due to their good electrical and thermal conductivity, such as electrical components, sockets, wire joints, etc. In addition, its malleability and decorative properties also make it an ideal material for the production of furniture, decorations, clocks, etc. The brass row also has good mechanical properties, good plasticity in the hot state, acceptable plasticity in the cold state, good machinability, easy fiber welding and welding, and corrosion resistance.

Company Profile

Copper Channel is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of Brass Bar

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of Brass Bar

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

What problems may occur during the use of Copper Busbars?

Answer: Common problems include poor contact, loose connections, breaks, oxidation corrosion, etc. These problems may be caused by improper installation, harsh use environment, poor material quality, etc.

How to solve the problem of poor copper bus contact?

Answer: The connection of the copper bars should be checked regularly to ensure good contact. For copper bars with poor contact, the dirt should be cleaned in time, the wiring position should be adjusted, and the wiring terminals should be tightened.

What are the precautions for the installation and maintenance of copper busbars?

Answer: During installation, ensure that the copper bars are firmly connected and in good contact, and avoid excessive bending or stretching. During maintenance, the connection status should be checked regularly, and damaged copper bars should be replaced in time to maintain good conductive properties.

What factors affect the price of copper strips?

Answer: The price of copper busbars is affected by many factors such as copper price, production process, specifications and sizes, and market demand. Among them, fluctuations in copper prices have a greater impact on copper bar prices.

How to judge the quality of copper busbars?

Answer: It can be evaluated from the aspects of appearance, conductive properties, mechanical properties, etc. A high-quality copper busbar should have a smooth appearance and no damage; its electrical conductivity should be stable and reliable; its mechanical properties should meet relevant standards. In addition, factors such as product certification and brand reputation can also be considered.

How to prevent oxidative corrosion of Copper Busbars during use?

Answer: Measures such as coating an insulating layer, regularly cleaning surface dirt and oxides, and avoiding contact with corrosive substances can be taken to extend the service life of the copper busbar.