Copper Pipe SOS: Your Step-by-Step Guide to Stopping Leaks Forever

(How To Repair A Copper Drain Pipe)

Picture this: a drip under the sink, a weird puddle on the floor, that faint metallic smell of water meeting copper. A leaky copper drain pipe isn’t just annoying—it’s a ticking time bomb for your cabinets, floors, and sanity. Good news? Fixing it yourself isn’t as scary as it sounds. Grab your tools, roll up your sleeves, and let’s turn you into a pipe-saving hero.

First, find the leak. Dry the pipe with a rag. Run water down the drain. Watch closely. Look for drips, damp spots, or greenish stains (that’s corrosion waving a red flag). Mark the trouble area with chalk or tape. Got it? Now shut off the water. No fancy valves? Turn off the main supply. Empty the pipe by running the faucet briefly.

Time to play surgeon. Cut out the damaged section. Use a tubing cutter for clean edges. Twist it around the pipe until the blade bites through. Too tight a space? A hacksaw works, but go slow—ragged edges ruin the repair. Aim for a straight cut. Remove about 2 inches more than the damaged part. Throw the bad piece away.

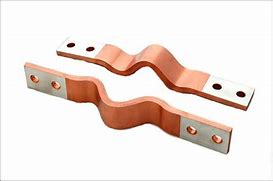

Next, prep the new copper pipe. Measure the gap. Cut a replacement piece slightly longer than the hole. Why? You’ll need extra length to fit couplings. Slide repair couplings onto both ends of the existing pipe. These shiny connectors are your new pipe’s best friends.

Cleanliness is key. Buff the ends of the old pipe and the new section with sandpaper until they shine like new pennies. Wipe off dust with a clean cloth. Any grit left behind? The solder won’t stick.

Grab flux—a gooey paste that helps solder flow. Smear it on the cleaned pipe ends and inside the couplings. Slide the couplings onto the old pipes. Push the new section into place. Line everything up straight.

Fire time. Use a propane torch. Heat the joint evenly, moving the flame around. Touch solder wire to the seam. If it melts and gets sucked in like magic, you’ve nailed it. Let it cool. Repeat for the other coupling.

Test your work. Turn the water back on. Check for leaks. Still dripping? Reheat the joint and add more solder. No drips? Congrats—you just outsmarted a plumbing disaster.

Bonus tip: Wrap a wet rag around nearby pipes while soldering. Prevents accidental heat damage. Wear gloves. Keep a fire extinguisher handy.

(How To Repair A Copper Drain Pipe)

Remember, practice makes perfect. Mess up the first try? Try again. Copper’s forgiving. Each repair makes you faster, smarter, and more likely to laugh in the face of future leaks.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)