Title: How to Cut in a Ball on Copper Pipe

(How To Cut In A Ball Valve On Copper Pipe)

When faced with the challenge of cutting a ball valve on copper pipe, it is crucial to have proper knowledge before attempting the task. There are several steps involved in doing so, which will help you ensure that your work is done effectively and safely.

Step 1: Determine the Design and Outline of the Ball Valve

Before starting with the actual cutting process, it is essential to understand the design and outline of the ball valve. This involves identifying the size of the ball valve and its components such as bolts, gasket, spring, and sleeve. The outline should include the necessary safety measures for the cutting process and the specific methods of operation required for the valve.

Step 2: Clean and Sanitize the Copper Pipe

Once you have identified the appropriate equipment and tool for the cutting process, it is important to clean and sanitize the copper pipe thoroughly. The copper pipe must be well-oiled and dry before proceeding with the cutting process. You can use a wire brush or a damp cloth to clean the pipe.

Step 3: Apply Mounting Materials

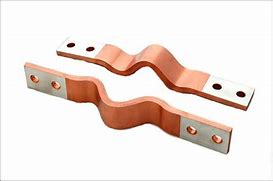

After cleaning the copper pipe, apply mounting materials such as bolts and screws to secure the valve. Ensure that the mounting materials are properly aligned and securely fastened. Use industry-specific screws to secure the mounting materials and attach them to the wall surface of the valve.

Step 4: Ensure Proper Orientation and Length

Ensure that the mounting materials are positioned correctly on the wall surface of the valve. If the mounting materials are not placed correctly, they may cause accidents during the cutting process. Ensure that the opening of the valve is properly sealed by pressing firmly against the wall surface.

Step 5: Secure the Ball Valve

Once the mountings are secure, place the ball valve on the wall surface of the pipe. Ensure that the ball valve is fully covered in clips or bars to prevent it from moving freely while being cut.

Step 6: Inspect and Test the Cutting Process

Check the condition of the cutting process after the has been inserted into the pipe. Check if there are any loose or broken parts and if the balls are seated properly. If the blades are not properlyaligned, the valve may not operate as intended.

Step 7: Maintain the Clothing and Equipment

It is important to maintain the clothing and equipment used for the cutting process. Ensure that the gloves are worn correctly and that the workplace is clean and organized. Regularly replace the replacement parts and check for any signs of wear and tear.

(How To Cut In A Ball Valve On Copper Pipe)

In conclusion, cutting a ball valve on copper pipe requires careful planning and execution. By following these steps, you can ensure that your work is done effectively and safely. It is also essential to take proper precautions to prevent accidents and ensure the longevity of the valve.