Flame-Kissed Pipes: Understanding the Art of Braizing Copper Pipes with a Gas Torch

(How To Braize Copper Pipes Together With Propane Torch)

Picture this: you, a propane torch in hand, bending fire to your will certainly as molten solder dancings into the seams of copper pipelines. Braizing isn’t simply a plumbing job– it’s a primal collaboration in between human resourcefulness and raw warmth. Neglect cold, leaky joints; this has to do with creating links that might last longer than the armageddon. All set to turn up the heat? Allow’s study the sizzling world of braizing copper pipelines.

Security First, Due To The Fact That Fire Attacks Back

Prior to we have fun with fires, allow’s talk survival equipment. Braizing involves open fire, molten steel, and the occasional rogue stimulate. Secure your eyeballs with security goggles– solder splatters aren’t a style statement. Heavy handwear covers? Non-negotiable. Cotton clothing? Yes, unless you desire synthetic fabric melting to your skin like a dystopian wax number. Maintain a fire extinguisher nearby, and clear your work space of anything flammable. (That includes your feline’s favored nap area.).

Tools of the Torch-Wielder’s Trade.

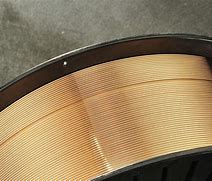

Gather your toolbox: a gas torch (the celebrity of the show), sandpaper or emery towel, change, flux brush, solder, and a cable brush. Oh, and the copper pipes themselves. Choose lead-free solder for alcohol consumption water lines– unless you’re into medieval-style poisoning.

Step 1: Cleanliness Is Beside Godliness (and Leak-Free).

Copper pipelines might look smooth, yet their surfaces conceal tiny gremlins like dirt and oxidation. Grab your sandpaper or emery towel and scrub the pipe finishes and fittings until they beam like pirate treasure. This isn’t simply for looks; it ensures the solder bonds like a lovesick barnacle.

Action 2: Change– The Unsung Hero of Braizing.

Change isn’t just goop in a jar. It’s the wonderful middleman that stops oxidation while you torch things. Rub a thin, also layer on the cleaned pipe ends and inside the installations using your flux brush. Consider it as sun block for steel– except instead of protecting against sunburn, it quits your joints from wearing away.

Step 3: Assemble Your Metal Problem.

Fit the pipes and installations together comfortably. No shaky links permitted. If it really feels loose, you’re inviting leakages to the party.

Step 4: Fire It Up (Responsibly, Pyromaniacs).

Spark your gas lantern and change the flame to a crisp blue cone. Hold the lantern concerning 2-4 inches from the joint, brushing up the flame uniformly around the pipeline. The goal? Heat the whole joint, not just one place. Visualize toasting a marshmallow– sluggish, even turning avoids charred disasters. Touch the solder to the joint; if it melts immediately, you’re gold. If not, keep heating.

Step 5: Feed the Solder, Not the Blazes.

Once the joint is warm sufficient, press the solder cord versus the joint opposite the fire. Capillary action will suck the liquified solder right into the space like a vampire at a blood bank. Keep feeding solder till a smooth, glossy ring kinds around the joint. Overdo it, and you’ll obtain balls; underdo it, and leakages will haunt your desires.

Step 6: Cool It, Professional.

Let the joint amazing naturally. Withstand need to speed up things up with water– thermal shock turns strong copper into a crumpled soft drink can. When trendy, clean away excess flux with a wet fabric to stop deterioration.

Repairing: When Fire Betrays You.

Dripping joint? Reheat and include more solder. Overheated pipeline transforming colors? You have actually blistered it. Remove the damaged section and start over. Solder not streaming? Filthy pipelines or inadequate warm. Channel your inner zen and try once more.

(How To Braize Copper Pipes Together With Propane Torch)

Braizing isn’t nearly dealing with pipelines– it’s about claiming dominion over fire. With practice, you’ll transform from a tentative torch-twirler into a copper-welding wizard. So get hold of that gas lantern, accept the warmth, and let your plumbing legacy start. (Just possibly maintain a fire extinguisher closer than your satisfaction.).

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)