Title: Can You Bend Copper Pipe Instinctively using Fitting?

(Can You Bend Copper Pipe Insted Of Using Fittings)

As an expert in metals engineering, I can confidently say that bendability is one of the most fascinating and important qualities that metal engineers take great care of when designing and manufacturing pipes. But how do you bend a copper pipe? And how do you use fitting to ensure maximum performance and efficiency? In this blog post, we’ll explore some of the techniques and tools involved in bendable pipe bending.

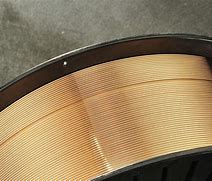

Firstly, let’s consider the materials used for bent copper pipes. The choice of material plays a crucial role in determining the overall shape and strength of the pipe. Porous metals like copper and silver are ideal for bendable pipe design because they are both flexible and lightweight, making them suitable for bending applications that require a large amount of flexibility. However, if the copper pipe has a dense inner layer or other constraints, then using thicker, stiffer metals like steel may be more appropriate.

Once you have chosen your material, it’s time to select the type of fitting you will use to bend the pipe. This can be done by selecting a special tool that is specifically designed for bent copper pipe bending, such as the-Hofer action, which uses a pin and handle to position and twist the copper pipe while bending it.

One of the most important aspects of bendable pipe bending is the use of fitting. Fitting refers to the process of carefully installing the fitting components on the ends of the pipe, so that they fit seamlessly and together. There are several types of fitting options available, including standard metal fitting bolts and neoplastic fitting tabs.

Using the right type of fitting will help ensure that the pipe bending process is smooth and efficient. For example, using a standard metal fitting bolt ensures that the installation is accurate and secure, while using a neoplastic fitting tab provides a more uniform fit and reduces the risk of twists and splits.

Another aspect of bendable pipe bending is the use of quality finishes. Finishes provide additional durability and resistance to damage during bending, ensuring that the pipe remains lengthen and strong over time. Common finishes include chrome plating, billet forged steel, and zinc-plated steel.

Finally, bendable pipe bending requires careful attention to detail, as well as a thorough understanding of the specific needs and specifications of the application. By using proper tools and techniques, you can ensure that your bendable pipe is delivered on time and meeting all required specifications.

(Can You Bend Copper Pipe Insted Of Using Fittings)

In conclusion, bendable pipe bending is a complex but rewarding process that requires specialized skills and knowledge. By following the techniques outlined above and using a variety of tools and materials, you can maximize performance and efficiency in bending copper pipe. Whether you’re working on small projects or larger-scale systems, bending copper pipe can offer a unique and rewarding opportunity for those interested in shaping metal structures.