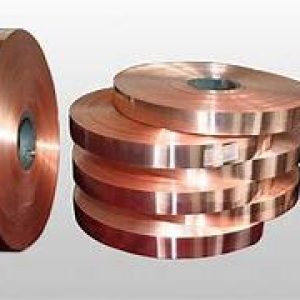

Overview of Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt

Copper strip refers to thin, flat, and flexible sheets or strips made from pure copper or copper alloys. Known for their excellent electrical conductivity, thermal conductivity, formability, and resistance to corrosion, copper strips are widely utilized in applications where these properties are of paramount importance. The thickness of copper strips can vary significantly, usually ranging from a few millimeters down to extremely thin foils, while widths can be tailored to suit specific application requirements. Copper strips are commonly manufactured through rolling processes, starting from copper ingots or thicker sheets and progressively reducing their thickness.

Features of Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt

-

High Conductivity: Like copper rods, copper strips offer excellent electrical and thermal conductivity, making them ideal for electrical and electronic components.

-

Formability: Copper strips can be easily bent, folded, or shaped without cracking, which is crucial for complex manufacturing processes.

-

Corrosion Resistance: Copper naturally forms a protective patina that inhibits further corrosion, ensuring its longevity in various environments.

-

Wide Range of Alloys Available: Copper can be combined with other metals to create strips with enhanced properties, such as increased strength, wear-resistance, or specialized thermal and electrical characteristics.

-

Flexibility: The thin and flexible nature of copper strips allows them to conform to curved surfaces or tight spaces, useful in wiring harnesses and compact electronic devices.

(Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt)

Parameters of Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt

The Special Copper Belt is designed for high precision copper belt machine H65 in English. It is made of special copper that has excellent performance and durability, ensuring consistent performance and improved efficiency.

One of the key features of the Special Copper Belt is its ability to withstand high temperatures and humidity levels. The use of special copper helps to reduce the amount of thermal stress that can be imposed on the belt, ensuring it remains strong and durable throughout the operation.

In addition to its strength and durability, the Special Copper Belt also has good electrical conductivity, which makes it ideal for use in the high-speed industrial applications where conductivity is critical. This means that it can provide an efficient and reliable connection between the belt and other equipment, reducing downtime and improving overall efficiency.

Another important feature of the Special Copper Belt is its ease of maintenance. Because it is made of special copper, it is less prone to wear and tear and requires fewer regular repairs. This means that the belt can operate more efficiently over time, resulting in reduced costs and increased productivity.

Overall, the Special Copper Belt provides exceptional performance and reliability in highprecision copper belt machines H65. Its strength, electrical conductivity, and easy maintenance make it an ideal choice for a variety of industries where electrical conductivity is critical.

(Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt)

Applications of Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt

-

Electronics Manufacturing: Copper strips are used in printed circuit boards (PCBs), connectors, transformers, and inductor coils due to their high conductivity and ease of processing.

-

Automotive Industry: They are integral to vehicle wiring harnesses, battery terminals, and various electrical components where flexibility and conductivity are required.

-

Building and Construction: Copper strips are used in roofing, flashing, and electrical grounding systems due to their durability and corrosion-resistant properties.

-

HVAC Systems: As part of heat exchangers, evaporators, and condenser coils, copper strips facilitate efficient heat transfer.

-

Telecommunications: Copper strips are found in cable shielding, providing electromagnetic interference (EMI) protection.

Company Profile

Copper Channel is a trusted global metal material supplier & manufacturer with over 12-year-experience in providing super high-quality copper products and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt

Q: What are the standard thicknesses for Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt?

A: Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt can be found in a wide range of thicknesses, typically starting from around 0.1mm up to a few millimeters, depending on the application.

Q: Can Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt be insulated or coated?

A: Yes, Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt can be insulated with materials like PVC, polyethylene, or varnish to protect against environmental factors or to enhance electrical insulation properties.

Q: Is Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt suitable for outdoor use?

A: Absolutely, copper’s inherent corrosion resistance makes it suitable for outdoor applications where exposure to weather conditions is inevitable.

Q: How does Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt compare to copper wires in terms of conductivity?

A: Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt generally has the same level of conductivity as copper wire of the same purity, but their larger surface area can allow for more effective heat dissipation in certain applications.

Q: Are there any specific cleaning or maintenance requirements for Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt?

A: Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt requires minimal maintenance. For cleaning, mild soap and water or specialized metal cleaners can be used, avoiding abrasive materials that might scratch the surface. Regular inspection for signs of corrosion or damage is recommended for critical applications.

(Special Copper Belt For High Precision Copper Belt Machine H65 Copper Belt)