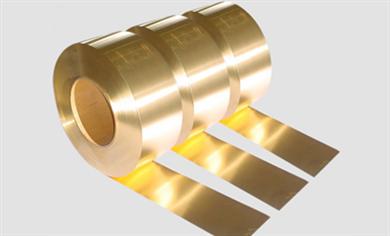

Brass Strip Description

Brass strip: According to its chemical composition, brass is divided into two types: ordinary copper and special brass. It has good mechanical properties and wear resistance and can be used to manufacture precision instruments, ship parts, gun shells, etc.

Brass belt/water tank belt: used for automobile water tanks, radiators, water chamber covers, etc.

Brass Strip Main Performance

The mechanical properties and wear resistance are very good,

Tensile strength σb (MPa):340~460

Elongation δ10 (%):≥25

Hardness:85~145HV

Note: Room temperature tensile mechanical properties of the strip

Sample size: thickness ≥0.3

Brass Strip Features

Excellent ductility, deep drawing ability, weldability and plateability.

Brass Strip Application

Electronics industry: Brass strips occupy an important position in the electronics industry. Due to its excellent electrical conductivity, brass tape is widely used in cables, electronic connectors, micromotor commutators, and frame materials for various electronic circuits and integrated circuits. In addition, key components in vacuum systems, electrical instruments, telephones, televisions, computers and other equipment are also often made of brass strips.

Construction and decoration field: In the field of construction, brass strips are often used to make door and window accessories, decorative strips and decorative elements due to their golden appearance and high gloss, adding beauty and artistic touch to the building. At the same time, brass belts are also widely used in the production of musical instruments, such as brass instruments, cymbals and cymbals, providing a material basis for their unique timbre.

Automotive and aviation industry: With the development of science and technology, brass belts are increasingly used in the automotive and aviation industry. It is often used to make key components such as seals, contact electrodes, thermal sheets, and battery connectors, providing important guarantees for the normal operation of cars and aircraft.

Heat exchangers and radiators: Brass strips are often used to manufacture heat exchangers, radiators and other thermal management equipment due to their good thermal conductivity. These devices can quickly transfer and dissipate heat to ensure the normal operation of machines and equipment.

Company Profile

Copper Channel is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of Brass Strip

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of Brass Strip

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

What is the production process of copper strips?

Answer: The production process of copper strips includes multiple steps such as smelting, casting, hot rolling, cold rolling, annealing, and finishing. By controlling parameters such as temperature, pressure, and cooling rate, copper strips with required properties can be obtained.

How to judge the quality of copper strip?

Answer: The quality of copper strips can be judged by examining its appearance (such as surface finish, flatness), physical properties (such as conductivity, tensile strength), and chemical composition.

Why does the copper strip bend and deform during use?

Answer: The bending deformation of copper strips during use may be caused by improper annealing process, uneven stress distribution during cold working, excessive impurities inside the material, or external environmental influences (such as temperature changes).

What is the reason for oxidation or corrosion on the surface of copper strip?

Answer: Oxidation or corrosion on the surface of the copper strip may be caused by a humid storage environment, contact with corrosive substances, improper surface treatment, or poor corrosion resistance of the material itself.

How to choose the appropriate copper strip specifications?

Answer: Choosing appropriate copper strip specifications needs to be considered based on specific application scenarios, such as current capacity, mechanical strength, usage environment and other factors. Cost factors also need to be considered.

Why does the copper strip break during use?

Answer: The fracture of the copper strip during use may be caused by defects in the material itself (such as pores, cracks), stress concentration during processing, harsh use environment (such as high temperature, corrosion), etc.

How to store and maintain copper strips?

Answer: When storing and maintaining copper strips, ensure that the environment is dry and ventilated, and avoid contact with corrosive substances. For long-term storage of copper strips, regular inspection and maintenance should be carried out to ensure stable performance.

What factors affect the price of copper strips?

Answer: The price of copper strips is affected by many factors, including raw material prices, complexity of production processes, market demand and supply, fluctuations in international copper prices, etc. The prices of copper strips of different specifications and qualities will also vary.