White Copper Plate Description

Element-free copper alloys with nickel as the main alloy are suitable for industrial sectors such as precision machinery, chemicals and medical devices.

White Copper Plate Features

It has good corrosion resistance, medium strength and high plasticity, can be processed by hot and cold pressure, and has good electrical properties. In addition to being used as structural materials, it is also an important high resistance and thermocouple alloy.

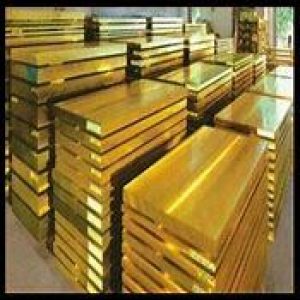

White Copper Plate Specifications

| Variety | Grade | Status | Specifications (mm) | Guideline | ||

| Thickness | Width | Length | ||||

| White copper plate

Iron white copper plate |

B5 B19 B25 BFe10-1-1 BFe30-1-1 |

R | 7~75 | >1500~2000 | 1500~4000 | Corporate standards |

| R | 7~60 | ≤2000 | ≤4000 | GB/T2040—2002 | ||

| Y、M | 3~10 | ≤600 | ≤1500 | |||

| Zinc white copper plate | BZn15-20 | M Y2 Y T |

3.0~10 | 300~600 | ≤1500 | |

| Note: Negotiable if not within the scope | ||||||

White Copper Plate Application

Electronic and electrical fields: White copper plates are often used to manufacture electronic devices, electronic connectors, and conductive components due to their good electrical conductivity and corrosion resistance. They can also be used to manufacture high-precision electronic equipment such as electronic components, circuit boards, and terminals, as well as relays, connectors, sockets, etc.

Automation and mechanical engineering: White copper plates play an important role in the manufacturing of mechanical parts and bearings. Due to their low friction coefficient and good wear resistance, they are often used to manufacture components such as braking systems, clutches, drive shafts, and bearings.

Decoration and construction: Due to its high strength and durability, as well as its good appearance, white copper plates are often used to make sculptures, door handles, handrails, lamps, and other decorations. At the same time, in the construction and decoration industry, it is also widely used in decorative materials such as copper doors, copper windows, and copper wall panels.

Marine engineering: White copper plates can effectively resist corrosion in the marine environment, so they are often used to manufacture marine equipment, pipes, valves, etc.

Chemical industry: Due to its good corrosion resistance, the white copper plate is widely used in the chemical industry to manufacture equipment such as reaction vessels, heat exchangers, pipes and valves.

Company Profile

Copper Channel is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of White Copper Plate

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of White Copper Plate

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

Question: What types of copper plates are there?

Answer: Copper plates can be classified according to their composition, manufacturing process and use. Common ones include red copper plates, brass plates, bronze plates, etc.

Question: What is the thickness range of copper plates?

Answer: Copper sheets are available in a wide range of thicknesses, from very thin foils to thicker sheets, depending on the production process and application requirements.

Question: How to calculate the price of copper plates?

Answer: The price of copper plates is affected by many factors, including copper purity, thickness, size, market demand and supply, etc. Generally speaking, the price is calculated based on the weight of the copper plate and the market copper price.

Question: How can copper plates be processed?

Answer: Copper plates can be processed by cutting, bending, stamping, welding and other methods to meet different shape and size requirements.

Question: How to maintain copper plates?

Answer: The copper plate should avoid contact with sharp objects during use to avoid scratches. Regularly clean the dust and dirt on the surface of the copper plate. You can wipe it with a soft cloth and avoid using corrosive cleaning agents such as strong acids and alkalis.

Question: How to judge the quality of copper plates?

Answer: The quality of a copper plate can be judged by observing its appearance, measuring its size and thickness, and conducting chemical composition analysis. A high-quality copper plate should have a flat surface, uniform thickness and good electrical conductivity.

Question: What are the environmental protection requirements for copper plates?

Answer: Copper plates should comply with environmental protection requirements during production and use, such as reducing the emission of waste gas, waste water and solid waste, and using environmentally friendly production processes and materials to ensure the environmental performance of the product.