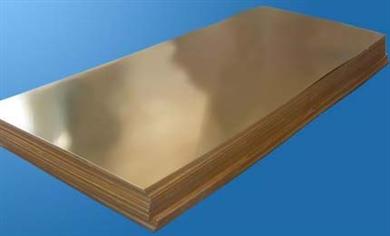

Brass Plate Description

- Ordinary brass is a binary alloy of copper and zinc. Due to its good plasticity, it is suitable for manufacturing plates.

- Special brass: In order to obtain higher strength, corrosion resistance and good casting performance, aluminum, silicon, manganese, lead, tin and other elements are added to the copper-zinc alloy to form special brass. Such as lead brass, tin brass, aluminum brass, silicon brass, manganese brass, etc. It can be used to produce various deep drawing and bending stress-bearing parts.

Brass Plate Features

It has good mechanical properties, good plasticity in hot state, good plasticity in cold state, good machinability, easy brazing and welding, and corrosion resistance.

Brass Plate Performance

It has good plasticity, high strength, corrosion resistance and good casting performance; it is cheap and is a widely used variety.

Brass Plate Maintenance

- Store in a clean and dry warehouse, and shall not be stored in the same warehouse as acid, alkali, salt and other materials. The warehouse must be ventilated and the humidity and temperature in the warehouse should be adjusted. Generally, the temperature in the warehouse is required to be maintained at 15~30°C and the relative humidity at 40 %~80% is appropriate

- Because copper is soft, avoid pulling, dragging, dropping, throwing, bumping or bumping when handling and stacking to avoid damaging or scratching the surface.

- If rust is found, use linen cloth or copper wire brush to wipe it off. Do not use wire brush to prevent scratching the surface. It is also not advisable to apply oil.

Brass Plate Parameters

Tensile strength σb (MPa): ≥290

Elongation δ10 (%): ≥30

Note: Room temperature tensile mechanical properties of the strip

Sample size: thickness ≥0.3

Brass Plate Specifications

| Variety | Grade | Status | Specifications (mm) | Reference Standard | ||

| Thickness | Width | Length | ||||

| Ordinary

Brass plate |

H62 H68 | R | 4~8 | 600~2000 | ≤4000 | GB/T2040—2002 |

| >8~60 | 600~3000 | ≤6000 | ||||

| >60~120 | 600~2000 | ≤4000 | Corporate standards | |||

| H62 H65 H68 H70 H80 H90 H95 |

Y Y2 M T |

0.2~0.49 | 600 | 1000~2000 | GB/T2040—2002 | |

| 0.5~2.5 | 600~1000 | 1000~3000 | ||||

| 3.0~4.0 | 600~2000 | ≤4000 | ||||

| >4.0~10 | 600~3000 | ≤6000 | ||||

| Brass plate for main piece of water tank and water chamber | H68 | M TM |

0.7~1.2 | 600~650 | 1000~1500 | GB/T2532—1997 |

| Brass plate for clocks | H65 H68 | M Y2 Y T |

0.30~1.50 | 600 | 1200~2000 | Corporate standards |

| Special purpose brass plate | H68 | M | 2.0~3.0 | 600 | 1000~2000 | |

| Iintricate brass plate | HPb59-1 | R | 4.0~8 | ≤550 | ≤3000 | GB/T2040—2002 |

| >8~60 | ≤600 | ≤4000 | ||||

| >60~80 | ≤630 | ≤4000 | Corporate standards | |||

| HPb59-1 HMn58-2 |

Y Y2 M |

0.5~2.5 | 300~500 | 1000~2000 | GB/T2040—2002 | |

| 3.0~4.0 | ≤550 | ≤4000 | ||||

| >4.0~10 | ≤550 | ≤4000 | ||||

| tin brass plate | HSn62-1 | R | 4.0~8 | 600~2000 | ≤4000 | |

| >8~60 | 600~3000 | ≤6000 | ||||

| >60~150 | 600~2500 | ≤4000 | Corporate standards | |||

| Y Y2 M |

0.5~2.5 | 300~500 | 1000~2000 | GB/T2040—2002 | ||

| 3.0~4.0 | ≤550 | ≤4000 | ||||

| >4.0~10 | ≤550 | ≤4000 | ||||

| Lead brass plates for clocks | HPb60-2 | Y Y2 T |

0.2—0.95 | 200~520 | 1200~2000 | Corporate standards |

| >0.95~6.0 | 200~550 | 900~2000 | ||||

| Brass plate for heat exchanger fixing plate | HSn62-1 | R | ≥9~60 | 300~3000 | ≤6000 | GB2531—81 |

Company Profile

Copper Channel is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality copper products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods of Brass Plate

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment of Brass Plate

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

Question: What types of copper plates are there?

Answer: Copper plates can be classified according to their composition, manufacturing process and use. Common ones include red copper plates, brass plates, bronze plates, etc.

Question: What is the thickness range of copper plates?

Answer: Copper sheets are available in a wide range of thicknesses, from very thin foils to thicker sheets, depending on the production process and application requirements.

Question: How to calculate the price of copper plates?

Answer: The price of copper plates is affected by many factors, including copper purity, thickness, size, market demand and supply, etc. Generally speaking, the price is calculated based on the weight of the copper plate and the market copper price.

Question: How can copper plates be processed?

Answer: Copper plates can be processed by cutting, bending, stamping, welding and other methods to meet different shape and size requirements.

Question: How to maintain copper plates?

Answer: The copper plate should avoid contact with sharp objects during use to avoid scratches. Regularly clean the dust and dirt on the surface of the copper plate. You can wipe it with a soft cloth and avoid using corrosive cleaning agents such as strong acids and alkalis.

Question: How to judge the quality of copper plates?

Answer: The quality of a copper plate can be judged by observing its appearance, measuring its size and thickness, and conducting chemical composition analysis. A high-quality copper plate should have a flat surface, uniform thickness and good electrical conductivity.

Question: What are the environmental protection requirements for copper plates?

Answer: Copper plates should comply with environmental protection requirements during production and use, such as reducing the emission of waste gas, waste water and solid waste, and using environmentally friendly production processes and materials to ensure the environmental performance of the product.